-

Posts

3545 -

Joined

-

Last visited

About Muhendis

Profile Information

-

Location

Buriram

Recent Profile Visitors

Muhendis's Achievements

-

Battery pack, fire detection and management?

Muhendis replied to Pink7's topic in Alternative/Renewable Energy Forum

What a hefty tomb that NFPA document is............. I had a quick skip through it and note there is a requirement for smoke detectors to be fitted for all ESS's. -

Battery pack, fire detection and management?

Muhendis replied to Pink7's topic in Alternative/Renewable Energy Forum

The point is that the stored, extremely high energy, should be isolated from the rest of the low power electronic world by normal protective procedures. If the battery itself should become unsociably unstable, then there is very little you or I can do about it. -

Battery pack, fire detection and management?

Muhendis replied to Pink7's topic in Alternative/Renewable Energy Forum

I think that may be dependant on global warming/sea level rise. -

Battery pack, fire detection and management?

Muhendis replied to Pink7's topic in Alternative/Renewable Energy Forum

I thought about fitting a smoke detector, but my feeling is that by the time smoke is detected it is too late to save anything electronical. Circuit protection is the best anti-fire regime. My battery balancers were connected direct to the batteries without any current limiting devices or fuses. It would have been nice if the company which supplied them had included a word or two about safety but, as usual, it is left to the individual to take whatever precautions are necessary. Batteries are chock full of big heavy power just itching to get out so any electronic devices connected to them need to be protected by a fuse. If a component in said electronic device were to fail short circuit, it would be nice if the thing failed to catch fire. -

How about a solar car port on a budget?

Muhendis replied to Crossy's topic in Alternative/Renewable Energy Forum

Those balancers can be a fire hazard if not fused. Been there. Done that. Extinguished the fire and replaced the nearest battery. -

Thai woman spills beans on corrupt cop’s love-linked traffic fines

Muhendis replied to snoop1130's topic in Isaan News

In the pre-social media days, these police activities would never come to light. Police would think themselves untouchable. That is the mindset which still persists even when caught with their fingers in the till. -

My New Solar and ESS room

Muhendis replied to Muhendis's topic in Alternative/Renewable Energy Forum

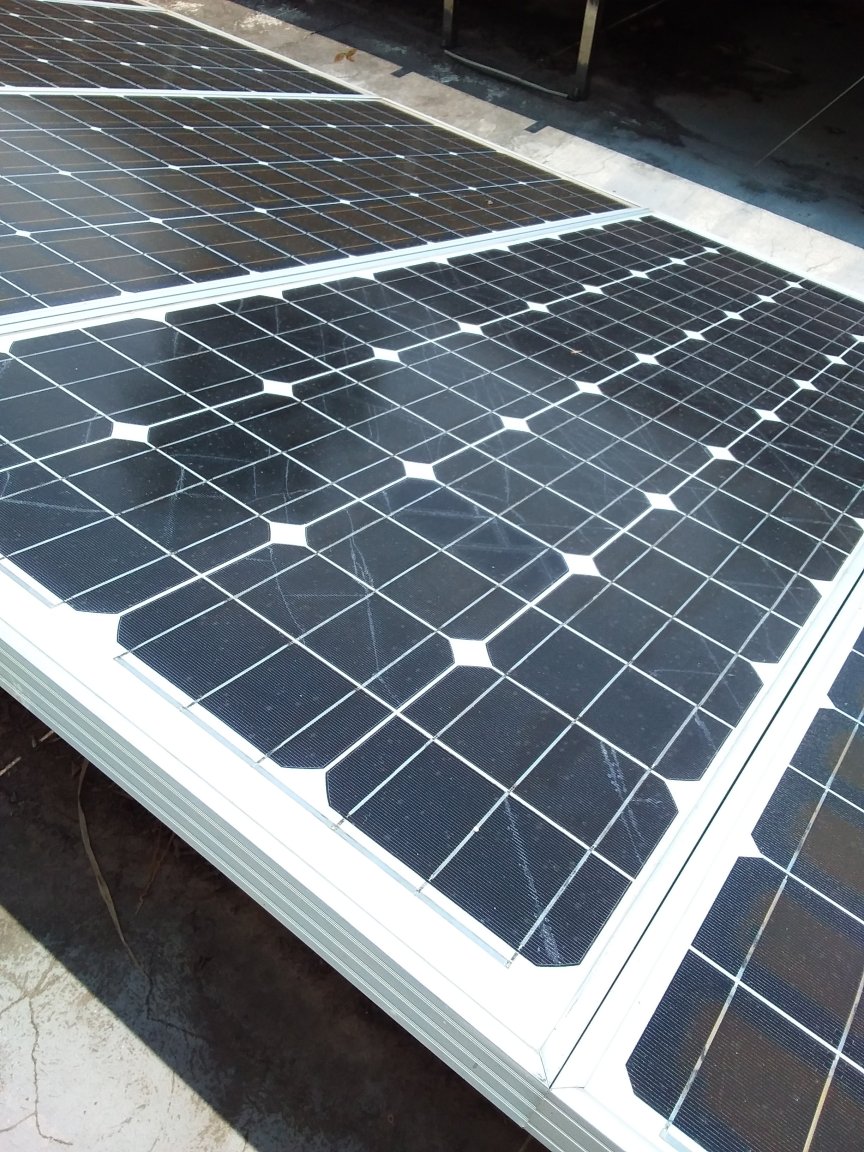

End of play today and all the new panels are all in place. Each panel is 550 Watt and seriously big and heavy. Size is 2.2 metres by 1.1 metres and, coming in at 35kg, highly recommended for industrial use. The silicon is 'N' type and half cell size. The flat roof is over 3 metres up so we (myself, wife, a nephew and a niece) did some interesting and innovative things with a ladder and some rope. I noticed that the frame of the panels is a bit floppy so I will be adding a bit more supporting truss work tomorrow. They don't make 'em like they used to. -

My New Solar and ESS room

Muhendis replied to Muhendis's topic in Alternative/Renewable Energy Forum

A couple of days ago I removed all the old panels from my carport roof and started assembling the steel supports for the new panels. -

My New Solar and ESS room

Muhendis replied to Muhendis's topic in Alternative/Renewable Energy Forum

I mentioned I would be replacing my 11 year old solar panels earlier. Why do I want to do that? The older panels are well worn out in the sun all day and the output is down enough for me to do something about it. Panels, particularly older tech ones will suffer from micro cracks, reduced intercell conduction, complete shattering of the front glass and UV light protection failure. Mine also suffered from being rated incorrectly with the sales pitch quoting them as 200W each but the label on the back making them to be 178W each. The micro cracks are in the silicon and will make it a bit tricky for electrons to travel from one side to the other. The burnt parts of the rear plastic layer in picture 2 are caused by the aluminium interconnections going resistive. The shattered glass in picture 3 is the result of the heat generated by the aluminium interconnections. Picture 4 shows the brown patches caused by failure of the UV protection layer. -

How about a solar car port on a budget?

Muhendis replied to Crossy's topic in Alternative/Renewable Energy Forum

Yeah. I had some similar excitement with my battery delivery. They were all on a single pallet and came in at a whopping 940 kg. I used a local courier from Bangkok to Buriram where I knew they had a forkin' lift. They fitted in the back of my Izusu 4x4 very well when I went and collected them. Downside is It cost 1k Baht to get them to the Bangkok depot from the Bangkok port warehouse. -

I'm going to backtrack on this a bit. The plywood is still a reasonable idea but, having gained some more knowledge I would supplement that with aluminium foil arranged to have free air on both sides. I changed my idea because I read this:- https://radiantbarrier.com/blogs/news/how-radiant-barrier-works-heat-gain-loss-in-buildings#:~:text=Most aluminum insulation has only,strikes its air-bound surfaces.

-

That's the sort of thing although it looks a bit thick and heavy. Thaiwatsadu also have some 5mm thick plywood which might be better

-

What I would do would be to screw some thin plywood or cement board to the underside of those, what look like, 30mm x 30mm steel roof panel supports. This would create an air gap which would reduce heat significantly. If you could also fill that air gap with fibreglass insulation, that would be even better.

-

April alcohol sales set to double, spiking road accidents feared

Muhendis replied to webfact's topic in Thailand News

Yeah! Go for it man. We're all behind you. -

How about a solar car port on a budget?

Muhendis replied to Crossy's topic in Alternative/Renewable Energy Forum

I should think you'd need some of your neighbours roof for that lot too. Are you thinking of selling power by any chance? 🙂